How does ATOM cold welding save cost for foundry

Due to technical or raw material reason, it is very common to have defect castings, normally around 10% to 30%. To solve the defect problems need more investment and effort to check every process like raw material / melting temperature / thermal conductivity / coating / molding line and other equipments. But even that still some percentage of defect castings maybe there. And for all these defect castings, around 60% to 80% of them only have few defect holes which can be repaired by our cold welding machine. So to repair these castings can salve a lot of cost.

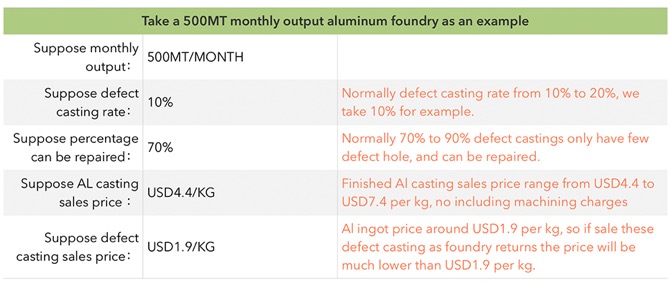

Cost calculation as blow:

Technology & articles

Welding demo is available at your location where we have distributors !

Base on above data, total defect castings : 500x10% = 50MT

Quantity of defect casting can be repaired : 50x70% = 35MT = 35000kg

Total value : 35000 x 4.4 = USD154000

If sale the defect casting as foundry returns : 35000x1.9 = USD66500

So every month can save cost : 154000 - 66500 = USD87500

So use our cold welding machine can save a lot of cost every month .

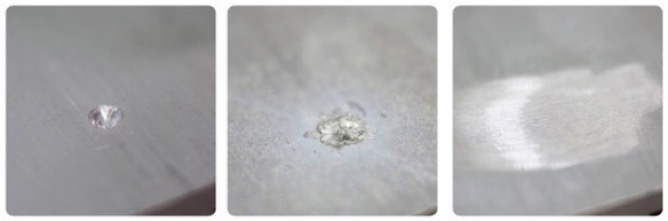

Defect hole After welding After grinding

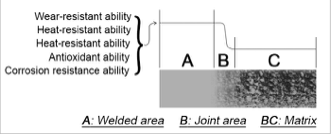

AWE-19US cold welding process is to use the high-energy power stored and release instantly between electrode and matrix with high frequency release, through air ionization channels formed between the electrode and matrix to generate an instant high temperature, high pressure micro-region.

When a positively charged welding electrode discharges a negatively charged workpiece, a small amount of welding material is transferred into the workpiece. AWE-19US utilizes the high frequency vibration of the new generation ultrasonic wave (more than 20,000 times per second) to realize repeated discharge transfer, so that the welding material is welded to the position of the workpiece which needs to be repaired.

Main features of AWE-19US:

1, Very low heat generated during welding, after welding can touch the surface immediately with finger , it is just room temperature. So no annealing no microstructure change for the casting, does not change the mechanical properties.

2, Suitable for all kinds of materials, as Aluminum / Ductile iron / Grey iron / Copper Brass / Steel and Stainless steel etc.

3, Can weld sand hole / porosity pin hole / small shrinkage / crack etc.

4, Can adjust the hardness of welding surface by select different welding electrodes, can be re-machined after welding.

5, The welding wire can be bent to any angle for welding special location and narrow deep locations, no argon gas required, low running cost.

Copyright © 2022 Atom welding equipments. All rights reserved.