ONE MACHINE SOLVES ALL DEFECT PROBLEMS

FULL DIGITAL CONTROL | 2400W POWER | NEW WELDING GUN

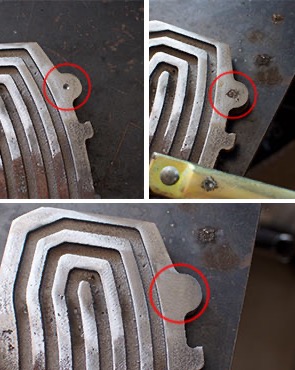

Porosity defect

Sand hole defect

Crack defect

Angle broken

Shrinkage defect

Blow hole defect

WHY NEED AN AWE-16A

Blow hole/sand drop/shrinkage are common defects for castings, defect casting percentage normally around 10% to 30% for a foundry. Those rejected castings will cause a big lost if they remelt them or sell at a cheaper price. The fact is that most of the defect castings may only have few defect holes and on not so important locations. Then AWE-16A cold welder will just be the right tool to repair them.

FULL DIGITAL CONTROL

Makes the power output more accurate

2400W POWER

Bigger power, More possibility

DUAL TEMPERATURE SENSOR

More intelligent machine temperature control

NEW WELDING GUN SYSTEM

Longer-lasting use and faster installation

LOW TEMPERATURE WELDING

Small heat input, no annealing, no deformation

MULTIPLE USES

Casting repair, mould repair, Tungsten coating, etc

WITH OR WITHOUT ARGON GAS

Argon gas is not always necessary, save cost

SMALL COLOR DIFFERENCE

Metallurgical combination small color difference

A PROFESSIONAL TOOL FOR CASTING DEFECT REPAIR

Electro-spark deposition cold welding process is using the high-energy power stored and release instantly between electrode and matrix with high frequency release, through air ionization channels formed between the electrode and matrix to generate an instant high temperature and high pressure micro-region. While ion state of the electrode materials in micro-melt into the matrix, forming metallurgical combination.

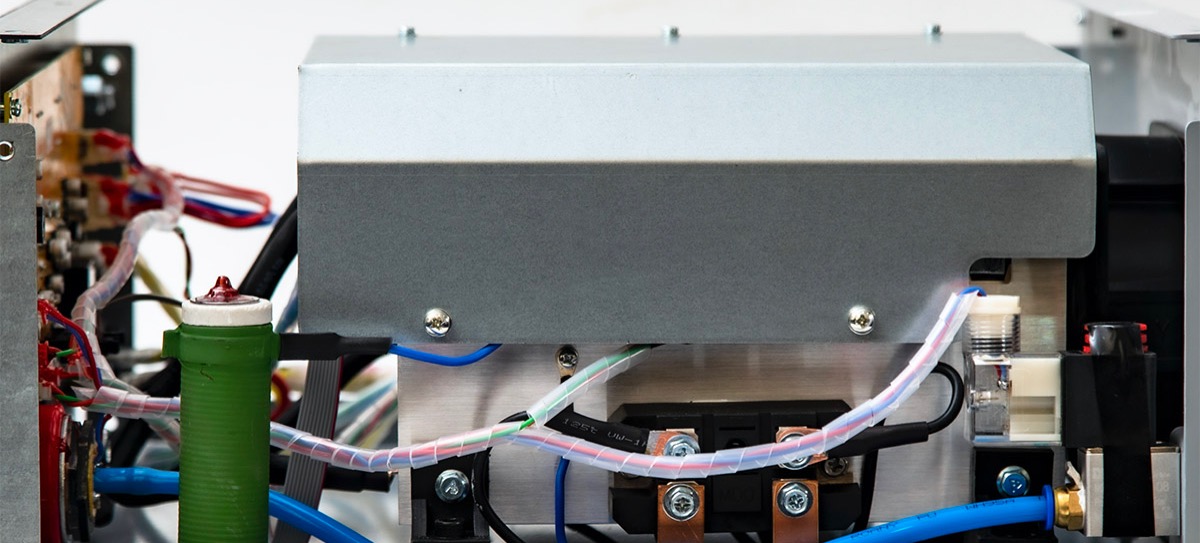

The new AWE-16A adopt full digital control, you can very easily and accurately adjust the machine power output.

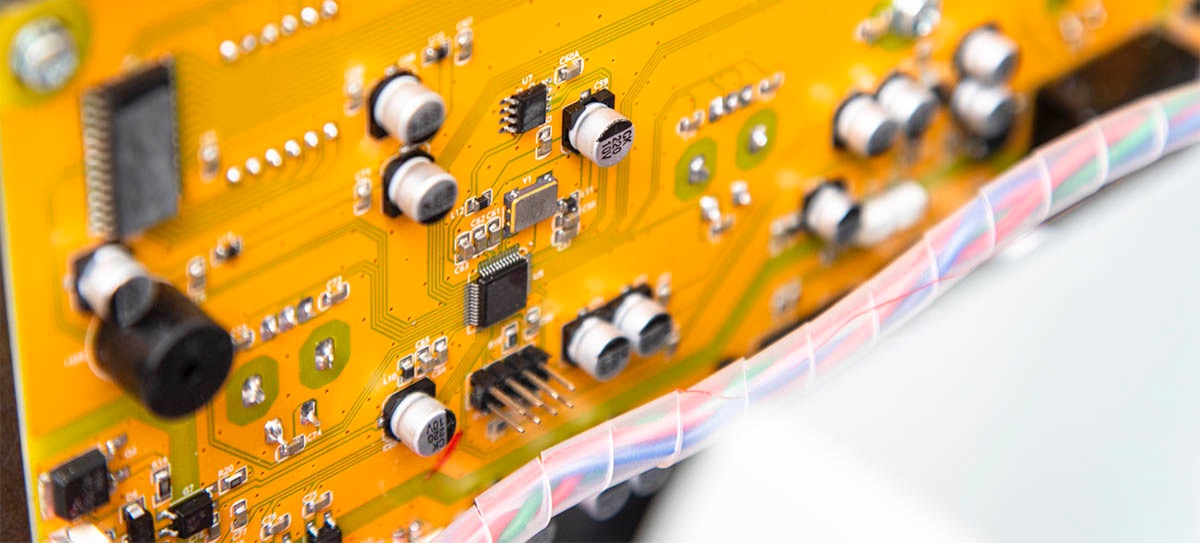

All industrial electronic components make the machine more durable and stable.

Power supply upgraded to 2400W, compare to old 1200W power the welding speed has improved a lot. Now you can weld even bigger holes with faster welding speed. Bigger power supply also makes the machine more stable, longer time continuous welding without power drop.New AWE-16A equipped with anti-interference components, which can effectively resist the voltage fluctuations generated when the surrounding large equipment start or stop.

Many of our customers use AWE-16A in a production environment, where metal dust is generated and short circuits can easily be triggered.

Therefore, the new machine is equipped with a metal dust cover at the top of the main control board, which can effectively isolate the influence of metal dust.

We listened to the feedback of our customers and continuously improve the performance of welding gun system. New designed welding gun interface more easily to plug in, not easy to damage even if plugged in and out frequently. The new welding gun eliminated external copper brush, so heat generation is smaller and using life is longer. The holding part of the welding gun is coated with Teflon, It can effectively block the heating from welding gun and makes it more comfortable to hold.

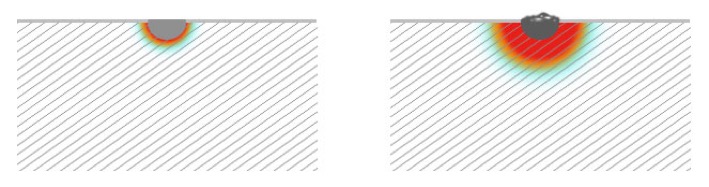

Very small heat affected zone

No change of micro structures

Use cold welding technology, you can touch the welded surface immediately after welding. You will feel the surface just worm not hot. Very small heat transferred into the casting compare to traditional welding machine.

No annealing and keep the mechanical structure unchanged.

ATOM cold welding

Heat affected zone

Traditional welding

Heat affected zone

Metallurgical bonding

Strong combination strength

Cold welding process will form a metallurgical combination.

To use the right type of electrode cold welded surface will strongly combined into the casting. Will not drop during machining or grinding.

Suitable for all types of castings

Ductile iron

Auto parts / Windmill casting

Gray iron

Cylinder / Textile machinery

Steel

Mould / Casting

Aluminum

Engine parts / Automobile hub

Copper

Power electrical facilities

Silver

Industrial / Crafts

Cast iron

Pump / Industrial castings

Brass

Ship parts / Precision instruments

Other alloys

Auto parts / Industrial parts

The welded area can be

re-machined

Casting welded by traditional welding machine can not be re-machined due to the welding hardness, but welded by ATOM cold welding machine you can re-machine the welded area again by CNC or grinding tool.

Also choose different type electrode will get different welding hardness, our professional will help you to choose the right type of electrode to match your castings.

TUNGSTEN COATING

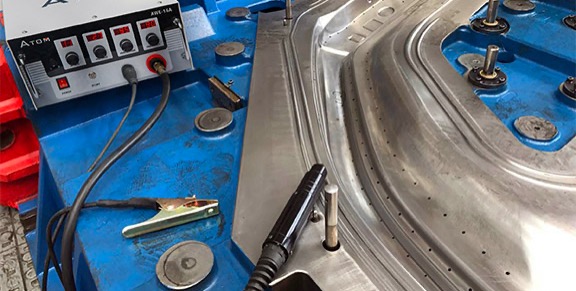

MOULD REPAIR

AWE-16A can also be used for tungsten coating.

This process can increase several microns for the surface which can be used for surface hardening or making the surface rough to increase friction.

AWE-16A is a good tool for mould repairing.

It can repair small damage/crack/scratch for mould to extend using life.

Stable performance, easy to use

Product quality is the foundation of company survival, so we adopt advanced production equipment and strict quality control. Each machine will be tested for continuous high current operation for 48 hours before leaving the factory, so as to ensure the smooth operation of customers after long-term and high-intensity use. In addition, each machine will be subject to 24-hour vibration test before packaging to ensure that parts will not fall off during transportation.

Full digital control

48 hours high current working test

24 hours vibration test

AWE-16A cold welding machine

Can be your best tool to repair casting defects and reduce rejections

AWE-16A PARAMETERS

MODEL:

AWE-16A

INPUT VOLTAGE:

AC220V 50/60Hz

POWER OUTPUT:

2400W

VOLTAGE RANGE:

20-100V

FREQUENCY:

WEIGHT:

50-500HZ

23KGS

OUTPUT PERCENTAGE:

MACHINE SIZE:

20-160%

405*210*450MM

WELDING ROD DIA.:

1.0 - 3.2MM

COOLING:

AIR

Copyright © 2022 Atom welding equipments. All rights reserved.